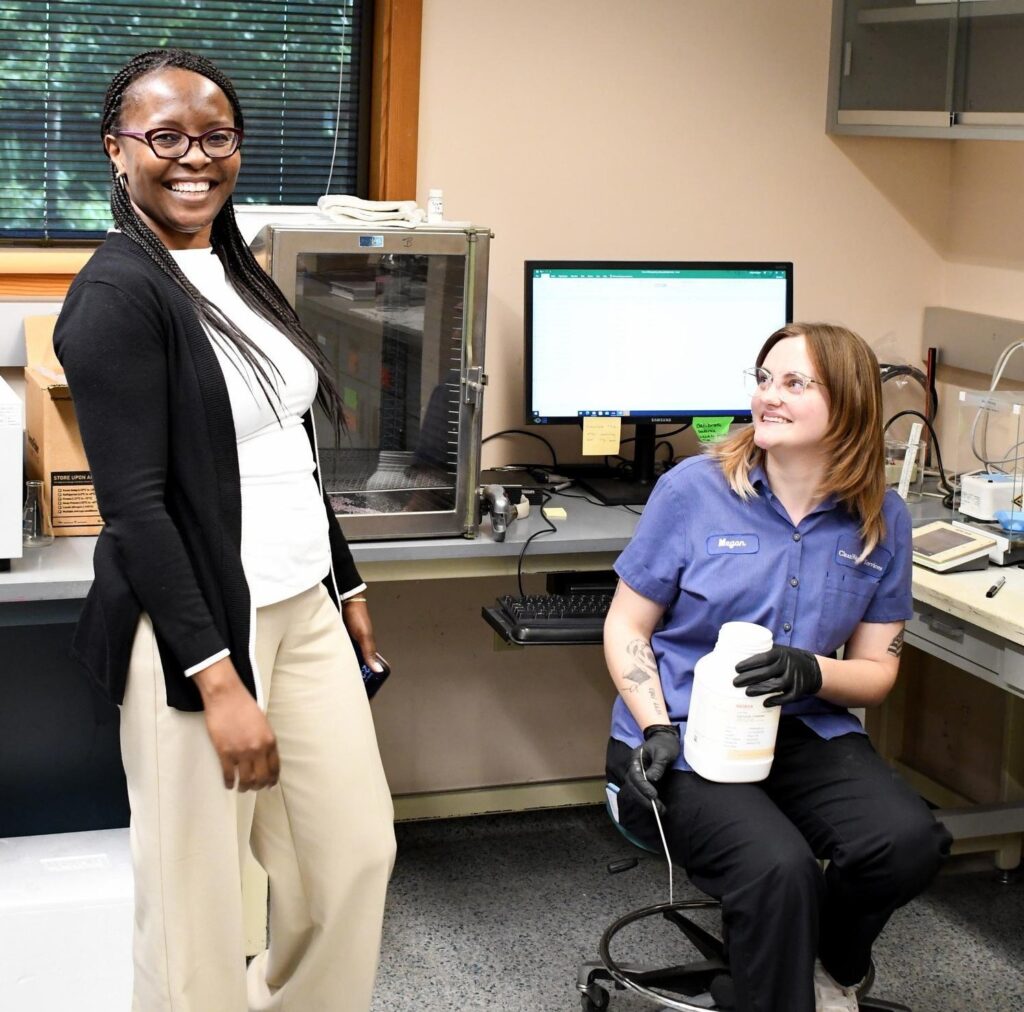

There’s a lot of science involved in treating wastewater and managing stormwater in the uniquely challenging Tualatin River Watershed. A sizable portion of that science takes place in the Clean Water Services (CWS) Water Quality Laboratory, where chemists perform over 100,000 water quality analyses a year.

In this Q&A, Laboratory Manager Karen Chichetu gives us an inside look at why the lab is so important to the work CWS does to protect our community’s health and the environment, how having an in-house lab saves ratepayer dollars, and why we’re building a new lab facility, known as RIPL.

What does the CWS Water Quality Laboratory do?

Karen Chichetu: The CWS Water Quality Laboratory provides sampling and testing services for CWS and our industrial, city, and university partners. This work involves routine sampling and analyzing of plant wastewater, biosolids, river water, stormwater, and industrial discharges. To ensure compliance with CWS’ National Pollutant Discharge Elimination System (NPDES) permit, the lab tests various water quality parameters like bacteria, nutrients, toxins, metals, and more.

Why is this testing important?

KC: Our testing helps protect public health and water resources by identifying pollutants and assessing potential risks of pollution. It ensures that we comply with regulatory requirements and supports CWS’ restoration and enhancement efforts by providing important data that help us make informed decisions to protect the Tualatin River for the people, farms, industries, and fish and wildlife that depend on the river.

Who uses CWS lab testing services?

KC: Our services are used by a range of CWS programs and external partners, including:

- CWS water resource recovery facilities (WRRFs) and other programs. CWS staff use data from the lab for research, ecological enhancement projects, planning for future regulations, and to inform the treatment processes at our WRRFs.

- Incident response. The lab analyzes samples from incidents such as sewage overflows, unidentified contaminants, and spills of commercial or residential waste to determine their source and any threat or risk to public health and safety.

- Industries. Companies in Washington County rely on our testing to ensure they meet water quality requirements for discharging industrial waste from their facilities to our WRRFs.

- Other cities and government agencies. We work with partner cities and other agencies to respond to discharge incidents in Washington County. The lab regularly conducts follow-up sampling and analysis in response to sanitary sewer overflows and related issues in Washington County.

How does CWS having an in-house laboratory benefit ratepayers?

KC: Keeping testing in-house helps us control costs, because outsourcing lab testing is expensive. When we outsource, we must pay not only the costs of sample analysis but also expedited shipping and transportation costs, because many of the required analyses are time sensitive. For example, analysis of PFAS by a commercial lab costs roughly $550 per sample. CWS invested in bringing this analysis in-house, which will provide a return on investment in two to three years.

Did You Know?

CWS is among the utilities leading the nation in per- and polyfluoroalkyl substances (PFAS) research, and is working with local industries to reduce PFAS in the Tualatin River Watershed. Learn more.

Onsite testing also ensures quicker turnaround times. This is important to our treatment plant operators because it allows them to integrate test results into daily operating decisions and respond accordingly to optimize treatment plant processes to maintain compliance. This reduces the risk of permit violations, which come with costly penalties that could impact ratepayers. More timely data also helps CWS leaders, engineers, and others make better, data-driven decisions. Faster turnaround time allows pretreatment staff — who work with the industries that discharge into our treatment facilities — to track pollutants to their sources so they can be promptly treated or controlled, providing better protection of the Tualatin River and the environment.

Having an in-house laboratory also allows CWS to:

- Respond day and night to emergencies such as sewage overflows or other contamination events, helping protect public health and the environment without delays.

- Conduct research that leads to innovative ways to control pollutants and lower costs for ratepayers. This would not be possible if we had to pay an outside laboratory to conduct these analyses.

- Provide better quality control of samples and analyses. Having our own lab allows us to implement and maintain the highest level of quality control, ensuring reliable data that leads to more informed decisions. This is particularly important for samples that must be analyzed very quickly after collection. Sending these to a commercial lab requires expensive overnight shipping in ice-filled coolers, and there have been many instances where samples were not analyzed in time.

How does the lab ensure quality and accuracy in testing?

KC: Our lab staff has over 200 years of combined experience at CWS and a range of science degrees in biology, biochemistry, chemistry, marine sciences, and environmental sciences. Over the last year alone, our chemists have tested 75,400 samples and delivered 300,000 analytical results under an extensive quality assurance and quality control (QA/QC) program. That program includes:

- Adhering to approved published analytical procedures. We use standard published methods, including those in the Standard Methods for the Analysis of Water and Wastewater, Title 40 Part 136 of the Code of Federal Regulations, and techniques approved by the Environmental Protection Agency.

- Regular calibration. All our instruments are routinely maintained and calibrated as outlined in our standard operating procedures.

- Chain of custody. We implement strict procedures to track each sample and prevent contamination.

- Quality control samples. We include control samples in every batch to ensure the reliability and accuracy of our data. Our data is traceable to accepted standard reference materials.

- External audits. Our lab participates in blind proficiency testing and consistently achieves a passing rate of over 98%.

Why is CWS building another laboratory?

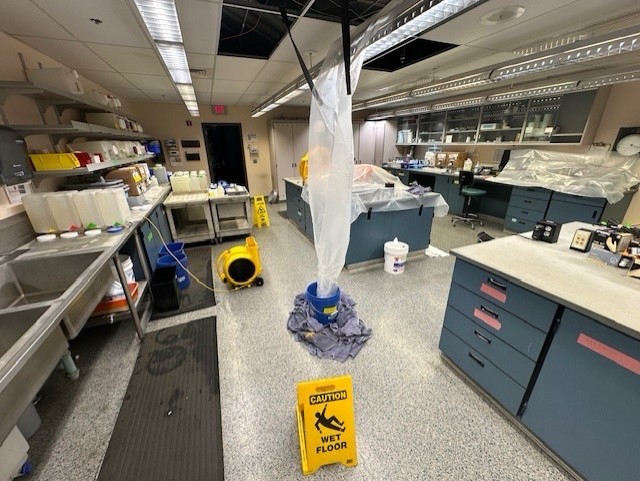

KC: The current lab building is nearly 30 years old. Systems are failing, requiring substantial upgrades. For example, the fume hood duct work is corroded, and most of the fume hoods are inoperable. The uninterruptible power supply, which is critical for lab operations, has been out of commission for years. During hot weather, the HVAC system isn’t able to keep temperatures in some areas of the lab below levels that can affect the performance of some scientific instruments.

Finally, the number and types of analyses required to maintain current and future compliance with environmental regulations is increasing, and the lab is running out of space and utilities. In some cases, spaces are currently overloaded with more analyses and people than they were meant for. Laboratory functions have been split into different facilities due to space constraints, which is inefficient.

The new RIPL lab building will allow CWS to better respond to future regulatory demands and will have security for chain of custody of samples and sample drops.

Learn more about RIPL here, and about RIPL and other building projects in this CWS Occupied Building Projects Status Update and our Budget Q&A.